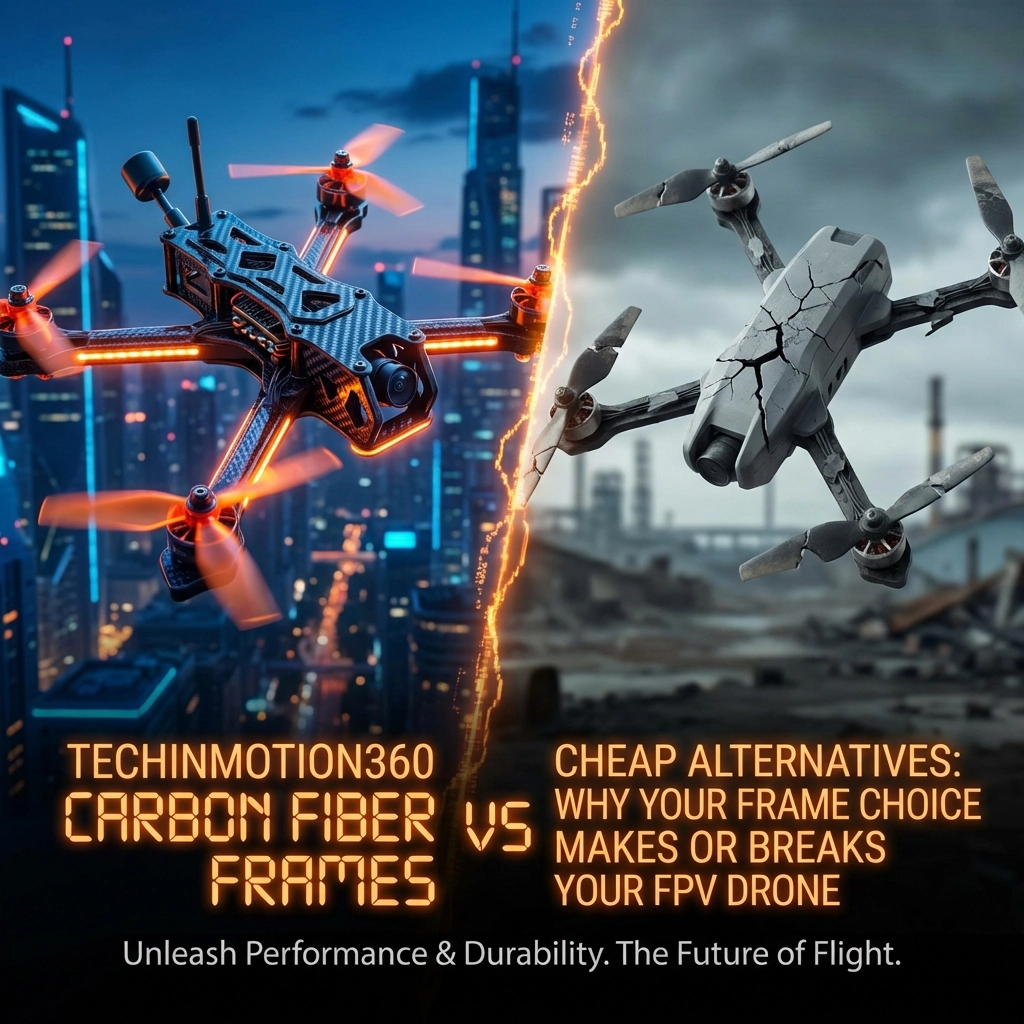

Let me paint you a picture. You’ve just spent three months learning to fly FPV, dropped serious cash on a decent camera, quality motors, and a flight controller that rivals a small computer. Then you slapped all of it onto a $15 frame you found on some random marketplace because “a frame is just a frame, right?”

Wrong. So very wrong.

That budget frame is about to become the weakest link in your entire setup. And when it fails, not if, when, it’s taking everything else down with it. I’ve seen it happen dozens of times, and it never gets easier to watch someone learn this lesson the hard way.

The Hidden Cost of “Saving Money” on Frames

Here’s the thing about cheap frames that nobody tells you upfront: they’re not actually cheap. Not when you factor in replacement parts, crashed components, and the sheer frustration of dealing with subpar materials.

Budget frames typically use lower-grade carbon fiber, or worse, carbon fiber mixed with fiberglass to cut costs. The result? A frame that looks decent on paper but crumbles under real-world stress. That first hard landing? Crack. That tree branch you clipped during a proximity run? Shattered arm. That slightly rough landing on asphalt? Split bottom plate.

Quality carbon fiber frames, like the ones we work with at TechInMotion360, use properly layered, high-density carbon that’s designed to handle the abuse FPV flying dishes out. The difference isn’t just marketing speak, it’s physics.

Understanding Carbon Fiber Quality

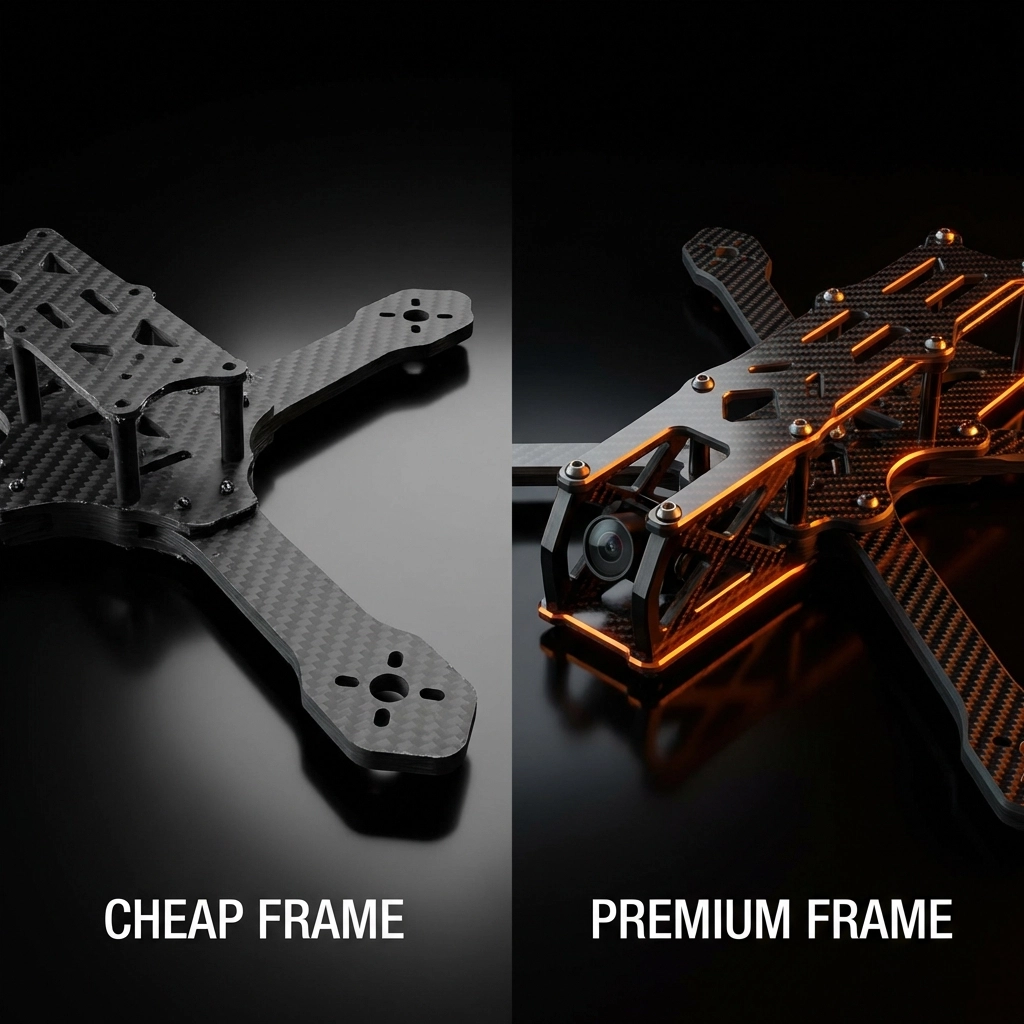

Not all carbon fiber is created equal. This is probably the most important thing you’ll learn from this entire post, so pay attention.

Cheap carbon fiber characteristics:

- Thin, inconsistent layering

- Lower carbon-to-resin ratio

- Brittle failure modes (shatters instead of flexing)

- Rough, unfinished edges that can cut wires

- Poor vibration dampening

Quality carbon fiber characteristics:

- Multiple precisely-layered sheets

- Higher carbon content for strength-to-weight optimization

- Controlled flex before failure

- Chamfered, smooth edges

- Better vibration characteristics for cleaner footage and stable flight

The research backs this up: carbon fiber’s advantages include being lighter, stronger, less dense, and stiffer with more responsive handling characteristics. Quality frames resist corrosion and don’t experience the fatigue issues that plague cheaper alternatives over time.

The Crash Test Reality

Let’s talk about what actually happens when you crash, because you will crash. Everyone does. It’s part of flying FPV.

With a quality carbon fiber frame, a moderate crash typically results in:

- Minor scratches or scuffs

- Maybe a bent prop (easily replaced)

- Your electronics staying safely mounted

- Getting back in the air within minutes

With a budget frame, that same crash often means:

- Cracked or broken arms

- Motor mounts that snap clean off

- Standoffs pulling through weakened material

- A pile of expensive components scattered across the ground

I’ve personally seen pilots go through four or five cheap frames in the time a quality frame would still be flying strong. When you add up those replacement costs, plus the time spent rebuilding, plus any collateral damage to other components… that “savings” evaporates pretty quickly.

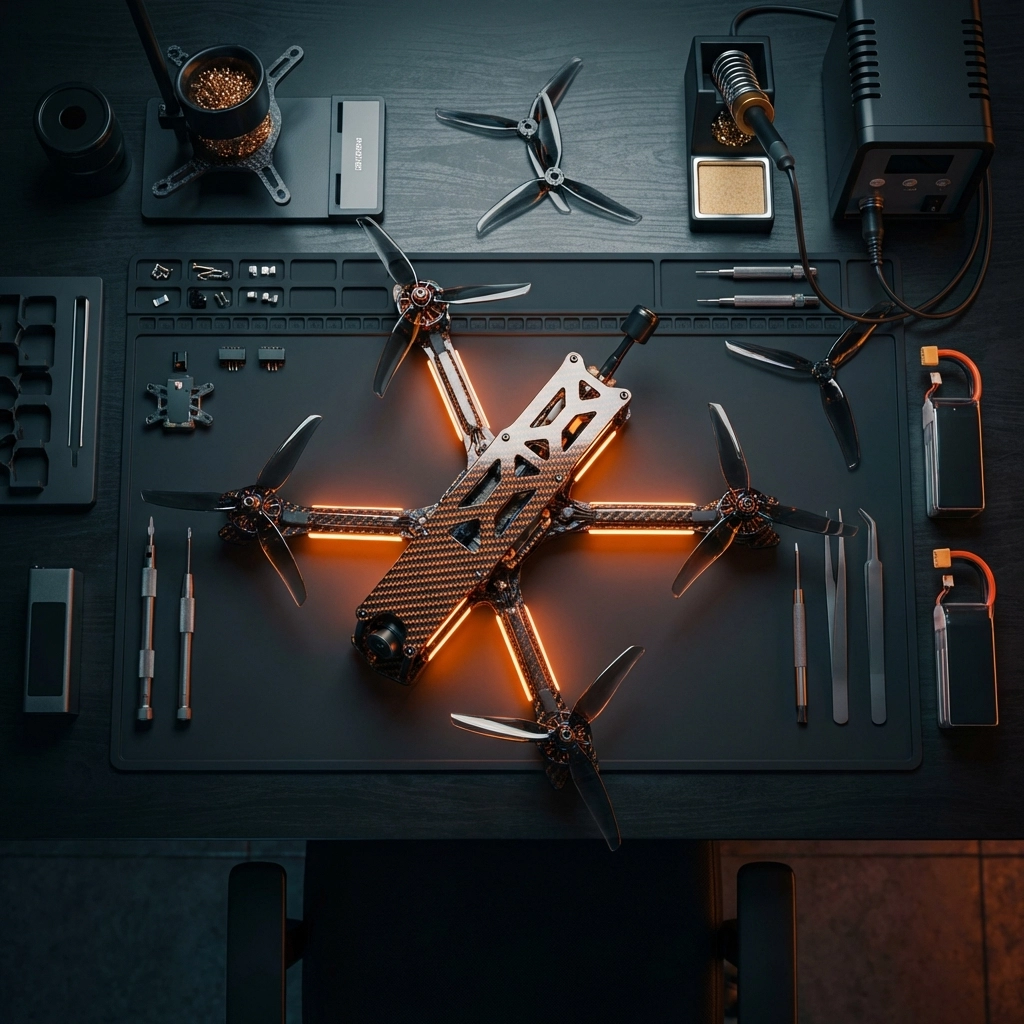

Weight vs. Durability: Finding the Sweet Spot

Here’s where it gets interesting. You’d think lighter always equals better in the FPV world, but that’s an oversimplification.

Research comparing similar-priced frames showed an aluminum frame at 216 grams versus a carbon fiber frame at 240 grams. That 24-gram difference? Barely noticeable in flight. What IS noticeable is how each material handles stress.

Quality carbon fiber frames hit the sweet spot: they’re light enough for agile flight characteristics while being strong enough to survive your learning curve. Cheap frames often sacrifice structural integrity for weight savings, giving you a drone that flies great until its first real impact.

The goal isn’t the lightest possible frame, it’s the best strength-to-weight ratio you can achieve. That’s where premium carbon fiber shines.

Flight Characteristics You Can Actually Feel

Beyond durability, your frame choice directly impacts how your drone flies. This isn’t placebo effect stuff, it’s measurable.

Vibration tuning becomes a real factor with material choice. Your flight controller is typically calibrated assuming certain vibration characteristics. Cheaper frames with inconsistent carbon quality or poor design create noise in your system that:

- Degrades your video footage

- Makes tuning more difficult

- Can trigger unwanted flight controller responses

- Reduces overall flight smoothness

A well-designed carbon fiber frame acts as a stable platform for all your components. Everything stays where it should, vibrations get dampened appropriately, and your flight controller can do its job without fighting bad data.

The Long-Term Investment Perspective

Let me break down the real math here:

Scenario A: Budget Frame Approach

- Initial frame cost: $15-25

- Average lifespan before replacement: 2-3 months of regular flying

- Collateral damage from frame failures: $50-150 per incident

- Annual frame costs: $60-100+ just in frames

- Total first-year cost: $150-300+ including damaged components

Scenario B: Quality Frame Investment

- Initial frame cost: $45-85

- Average lifespan: 12+ months of regular flying

- Collateral damage: Minimal (frame protects components)

- Annual frame costs: $45-85

- Total first-year cost: $45-85

The numbers don’t lie. Spending more upfront on a quality frame actually saves you money over time. Plus, you get better flight characteristics, cleaner footage, and way less frustration.

When Your Frame Does Need Attention

Even the best frames eventually need maintenance or upgrades. That’s just reality. The difference is how often and how extensive that maintenance needs to be.

If you’re running a quality setup and something does go wrong, our Basic Maintenance & Repair service can get you back in the air quickly. For more complex issues or if you want to optimize your build further, our Advanced Support Package covers performance tuning and troubleshooting.

The point is: with a quality frame, maintenance is occasional and manageable. With a cheap frame, it’s constant and expensive.

Making the Right Choice

So what should you actually look for when choosing a frame? Here’s my checklist:

Material specs: Look for 3K or higher carbon weave, multiple layers, and published thickness specifications. If a seller can’t tell you the exact carbon specs, that’s a red flag.

Design features: Quality frames have chamfered edges, proper hardware, and thoughtful component mounting options. Check for reinforced motor mounts and adequate standoff spacing.

Reputation: Frames from established manufacturers with community feedback beat anonymous marketplace options every time.

Warranty/support: Does the manufacturer stand behind their product? Quality frame makers typically do.

The Bottom Line

Your frame is literally the foundation of your entire FPV drone. Everything else, your expensive camera, your tuned motors, your flight controller, all of it depends on that frame to keep it safe, stable, and flying.

Cheaping out on your frame is like building a house on sand. Sure, it might look fine at first, but it’s only a matter of time before everything comes crashing down.

Invest in a quality carbon fiber frame from the start. Your wallet will thank you. Your components will thank you. And you’ll spend way more time flying and way less time rebuilding.

Ready to upgrade your setup or need help choosing the right components? Check out our Performance Upgrade Package or browse our full range of FPV drone support services to get flying with confidence.

Have questions about frame selection or need help with your current build? Drop by the TechInMotion360 blog for more guides and tips.

Leave a comment